- +86 18118832647 [email protected]

- Bingang Industrial Area, Shamen Town, Yuhuan, Zhejiang, China

Loading ...

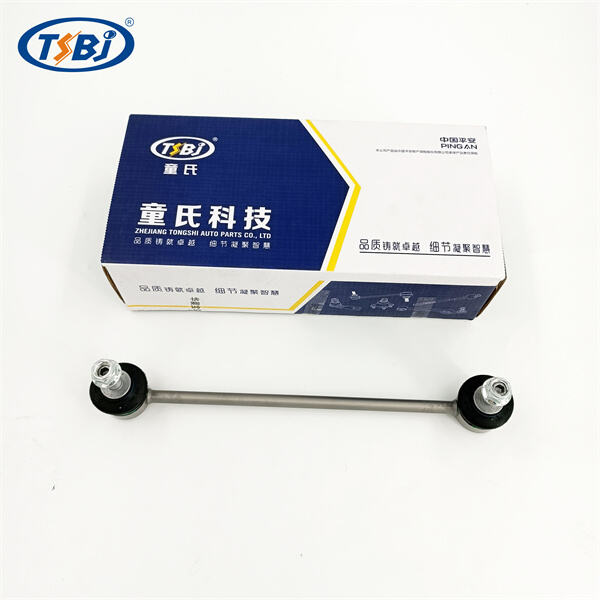

Offside Front Suspension Arm Ball Joint All You Need To Know

Care to add more performance in your car? An obvious win replacement to examine, if needed replace while your at it is the Lower Ball Joint on an Offside Front Suspension Arm. This key role comes with many benefits as well as advancements that are designed to meet the highest safety and performance demands during driving. This time, we are focussing on the key components of an hydraulic Type 35 drive shafts, what it does and how to judge its quality**- as well noting some application examples for different classes of car.

There are actually a number of reasons why the offside front suspension arm ball joint has become popular for this piece, from its output to its versatility. In the final analysis, it enhances performance through gains in traction and control. helping the car corner flatter on bushings It also leads to a more refined ride as it plays a role in reducing noise, vibration and harshness. A further benefit is improvements in both fuel economy and tire life Combined, these advantages result in a more comfortable and involving driving experience.

The front suspension offside arm ball joint has been the feature of many design changes and improvements all aimed at enhancing its operational capacity. The material used in this unit is characterized by its ease of use, among them steel (alcat) aluminum and polymers that are well known worldwide for their lightness but at the same time compatibility with domestic driving conditions have been well tried. Also a few manufacturers have started utilizing CNC milling, 3D printing and computer-aided design (CAD) with which they are able to manufacture even more precise parts making them extremely durable.

Even after the current selection process, for safety reasons we will still end up with the complete front suspension arm ball joint offside. It is in fact a part the joins both suspension system and wheel hub together to give your wheels firm support so that they can move smoothly while rotating. But in case something goes wrong or breaks bad things happen resulting much worse consequences e.g. premature tire wear, loss of control and even suspension collapse So to keep up with the minimum safety one can have it is essential that quality ball joints are used while inspecting them on regular intervals so as any signs for its wear can be easily identified.

have 5000+ models our products stock With complete packaging Offside front suspension arm ball joint, more than 20 representatives China The delivery time is between 1 7 days

manufacture Japanese American, Korean Germans, Chinese other Offside front suspension arm ball jointparts.

are able accept custom Offside front suspension arm ball joint samples, accordance with requirements our clients for production

Tongshi a proud recipient of IATF16949:2016 quality system certification,and have worked with Offside front suspension arm ball jointworld-renowned factories over ten years

Copyright © Zhejiang Tongshi Industrial Technology Co., Ltd. All Rights Reserved | Privacy Policy